RAW MATERIAL & WIRE PROCESSING

KIS sources material directly from high quality steel manufacturers. All the material is thoroughly inspected before processing. Each grade is marked and provided with a proper identification tag. After the inspection the material is given for processing (annealing & drawing). Wire Drawing is carried out to get the required wire size for cold forging the parts depending upon the size of fasteners to be manufactured. Each lot is identified with a unique heat number. The lots are 100% checked for chemical composition (by Spectrometer), metallurgical & mechanical Properties. All records are maintained and can be provided on demand.

HOT FORGING

Forging: Forging is the process of deforming metal into a predetermined shape using certain tools and equipment—deformation is accomplished using hot, cold, or even warm forging processes. It is the basic operation in most bolts and screws to give their desired shape. KIS has the capability to develop and forge highly special parts, Bolts/Screws/Studs etc. along with the vast range of standard fasteners.

Hot Forging

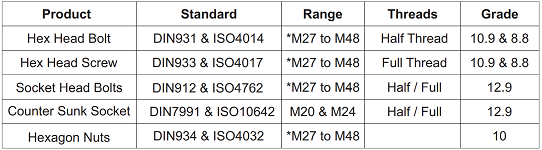

It is the process of forming the shape of the metal in hot condition into a predetermined shape. A metal is heated to the proper temperature by high-speed electric induction before it is inserted into a metal piece. Bolts are hot forged when the material is too large in diameter or it is not malleable enough.

* Below M27 we manufacture by cold forging

COLD FORGING

Forging: Forging is the process of deforming metal into a predetermined shape using certain tools and equipment—deformation is accomplished using hot, cold, or even warm forging processes. It is the basic operation in most bolts and screws to give their desired shape. KIS has the capability to develop and forge highly special parts, Bolts/Screws/Studs etc. along with the vast range of standard fasteners.

Cold Forging

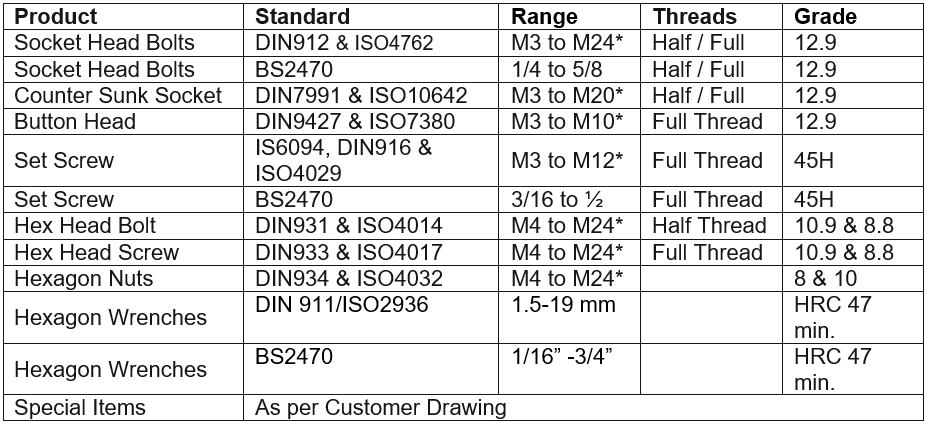

It is the process of forming the shape of a metal piece by external forces in ambient conditions. It is normally done at room temperature or near room temperature. At KIS, we do the cold forging on our fully automatic high speed multi station bolt formers. Our capacity includes a wide range of High Tensile Fasteners.

* Above M24 we manufacture by hot forging

SECONDARY OPERATIONS

KYOSHO is capable of doing many secondary operations in house of special turning components which includes boring, facing, tapping, turning, grooving internal-external, champering, theading etc.

We have high range of dowel pins getting manufactured IN-House for high end customers across the globe.

HEAT TREATMENT

High-strength or heat-treated fasteners are often required to handle the tensile, shear or combination loads on the bolted joints in demanding applications. Many demanding applications require high-strength fasteners in order to handle high tensile and shear stresses generated by the applied loads on the bolted or fastened joint. The Heat Treatment Department conducts hardening and tempering to ensure that the fasteners meet the required strength and hardness class. This is needed to prevent unacceptable safety risks in the application of the fasteners. The defining characteristic for product quality is core hardness. The requirement for this characteristic is that the product attains, at a minimum, 90 percent martensite grain structures.

At KIS, heavy investment has been done to install the latest and state of the art continuous furnace to ensure that the desired results are achieved every time. Regular maintenance and check-ups are done to maintain the same quality. All the data are stored and can be shown on demand.

SURFACE TREATMENT

Surface Treatment in Fasteners is done to prevent it from Corrosion and give artistic look.

We provide following surface treatment as per customer requirement:

- Zinc and Manganese Phosphate Coating on Automatic Phosphating Line

- Alkaline Zinc Plating, Trivalent Chrome & Hexavalent Chrome in White, Blue, Yellow, Olive Green & Black Passivation on an Automatic Plating Line Cadmium Plating / Nickel Plating / Anodizing

- Zinc Iron & Zinc Nickel Plating

- Geomet, Dacromet, Magni, Zinc Flake Coating

- Hot Dip Galvanizing

- MoS2 Coating

- Loctite (Note: It is not surface Finish)

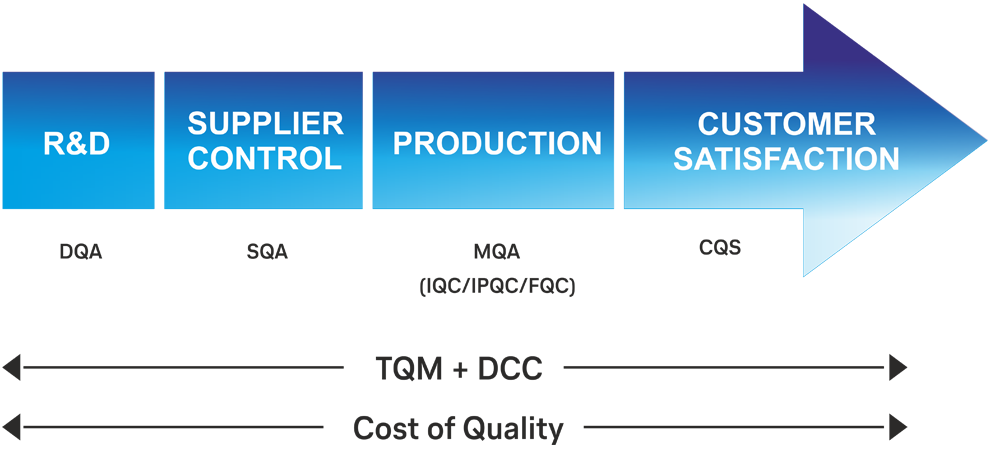

QUALITY

KYOSHO conducts rigorous quality assurance testing on all the fasteners it produces. Fasteners and Machine components are tested against stringent quality measures to guarantee performance and compliance for all the metrics based on industry standards or specific requirements.

KYOSHO has a QUALITY PLAN that ASSURES all parts will meet and exceed customer requirements. Our quality staff, with many years of experience in quality control and engineering, has complete understanding of all standards and specifications. Together with our “State of the Art” fastener testing equipment, you can be ASSURED of receiving the PRECISE, QUALITY TESTED fastener for your specific application.

We can furnish Dimensional Inspection Reports, Physical and Chemical Reports, and Certificates of Compliance upon request.

![]()

PLANTS

We have number of plants in which each plant is working on specific customers requirements.

Plant 1: IMT- Machined parts mostly Secondary Operations.

plant 2: Hissar Road -Manufacturing of Dowel pins of all range.

Plant 3: Hissar Road- Fasteners of all Range.